|

|

|

|

|

|

|

|

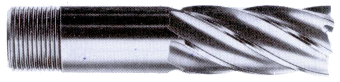

Reference DataTo be found here is a source of typical engineering reference data, including tapping drill sizes, and metric/imperial standard drill sizes which can also be used as a conversion lookup. As we find useful data we'll repeat it here as a central repository, not just for our benefit, but for yours too. Just to brighten things up a bit, some examples of typical engineering cutting tools follow; Twist Drill Normally used for making general purpose holes Centre (slocombe) Drill Used prior to drilling with a twist drill, where particular positional accuracy is required. This type of drill is used as an alternative to a centre punch and a hammer, where a lathe or mill is providing the positional accuracy, rather than scribed lines and marking out. Slot Drill Used in a milling operations where plunging cuts need to be made. The end of a slot drill is arranged to cut completely to the axis of rotation. In addition the diameter of a slot drill is made to an accurate size, and can therefore be used to machine fixed width slots in a single pass. They also work well as throwaway items in CNC routing/milling where a computer program "assumes" a known cutter size. When reground, typically only the end of a slot drill will be sharpened. End Mill End mills are used in milling operations where profiling must be performed and plunging is not required. On the end, an end mill does not cut completely to the centre of the cutter. Typically the outside diameter of an end mill should not be assumed. Where a side cut is made to a size, an initial cut should be made, the job measured, and then finished to size. When reground, typically both the sides and the end of the cutter will be sharpened. Hand Reamer Reamers come in many forms, for creating tapered and parallel holes. Most reamers are available in both hand and machine operated variants.

Screwing Tap A tap is used after drilling, to form a female screwthread inside a hole. Taps typcally come in three forms; Taper, Second and Plug.The tap pictured above is a specialist tap designed to thread holes in one shot, and is known as a gun-nose or spiral point tap. Ordinary taps differ by the arrangement of the nose;

"Taper taps" should not be confused with "taper thread forms" used commonly for producing gas tight joints on threaded pipes. Taper thread forms have a full thread depth along their length, but the actual thread is conical. Taper threaded couplings will only twist to a certain depth before becoming mechanically locked. Where a taper thread form is used the male thread is tapered, and the female thread may either be parallel or tapered. Screwing Die Dies are used for forming male threads on a rod or a machined protrusion from a job. Dies come in various styles, but typically the type used for creating new threads are known as split dies, as pictured above. Another type, die nuts, are not split and are not round but rather hexagonal to suit a spanner. Die nuts may be used to repair an existing thread "in the field". Split dies are normally used in a holder, with an adjustment screw that can wedge the die open, by a small amount. Using the die in this way, reduces the material that the die will remove as it cuts and can be used to form the thread in stages, in difficult materials. |

Copyright © Solid Fluid 2007-2025 |

Last modified: SolFlu Sat, 18 Jul 2009 20:55:30 GMT |